How to Take Your Boiler Room from Good to Great

Posted by Dan Kelley on

September 15, 2020

0

As a boiler service company, our technicians spend most of their time in a boiler room working on… you guessed

Understanding Steam Pressure Controls: Three Basic Functions

Posted by Dan Kelley on

August 26, 2020

Most steam boilers have three main controls that maintain the correct steam pressure inside the boiler and cause the boiler

Steam or Compressed Air? Same Pressure, Different Energy

Posted by Dan Kelley on

August 12, 2020

On a service call, a newer customer was showing us their steam-driven machines and how they operate with massive power

Summer: The Season for Sun, Fun, and Boiler Maintenance

Posted by Dan Kelley on

July 22, 2020

Don’t Wait Till Fall for a Service Call If your facility uses boilers for heat (whether steam or hot water),

Keeping Cool in the Heat

Posted by Dan Kelley on

July 8, 2020

During the summer months, the temperature in a boiler room can rise to anywhere between 80 and 100 degrees

Invisible Boiler-Busters, Part 2: Combustion

Posted by Dan Kelley on

June 24, 2020

In this next installment of the series we’ll examine how combustion in a steam boiler can change drastically over

Invisible Boiler-Busters, Part 1: Hard Water

Posted by Dan Kelley on

June 10, 2020

The steam boiler is at the foundation of what keeps your facility operational, which is why every maintenance and

The Fulton Vantage: This Boiler Is a Tank!

Posted by Dan Kelley on

May 27, 2020

When people call something a “tank,” they’re usually describing an object that’s robust, heavy duty, not easily broken, and

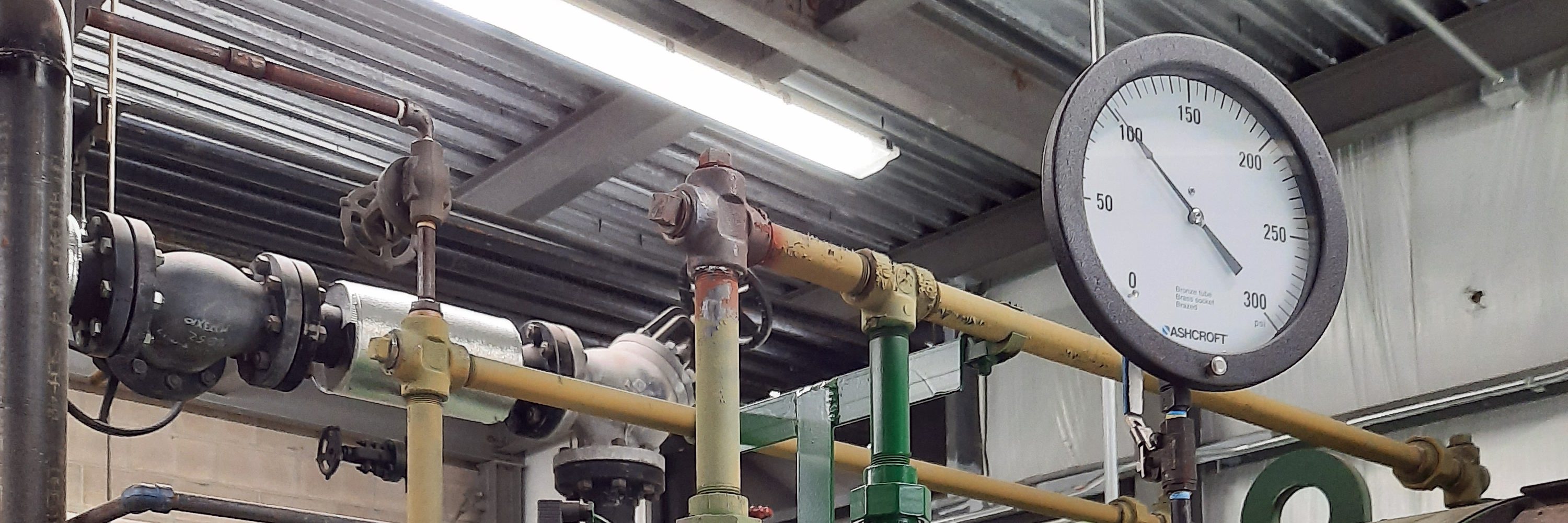

Understanding Boiler Pressure

Posted by Dan Kelley on

March 26, 2020

What defines a high pressure boiler? If you are unfamiliar with boilers and the power of steam, you might expect “high pressure” to